Fabricated bathroom refers to "the overall space with sanitary functions assembled by one or more pieces of sanitary ware, components and accessories in the factory or on-site assembly"(National Standard for Integral Bathroom "Residential Integral Bathroom" JGT183 -2011), that is, the bathroom room in the room will be taken out for standardized and large-scale production. Its basic components include: assembled components to control the form-roof panels, wall panels, waterproof plates, doors and windows; functional accessories to control the use function-connectors, sanitary ware, equipment and various practical accessories.

The overall bathroom has significant social benefits of energy conservation, environmental protection, and is characterized by standardization of product specifications, quality and quality, and construction processes due to centralized production and centralized installation. It is an important means to realize the industrialization of toilet houses.

Product highlights and advantages:The entire bathroom is mostly made of polymer environmentally friendly materials such as SMC, and a large amount of wet work on the construction site is avoided during the construction process. Therefore, compared with the traditional decoration methods of bathrooms, the overall bathroom has significant advantages in terms of green environmental protection, material saving, energy saving, water saving, and time saving, both in terms of materials and construction process.

SMC integrated bathroom production process

1. raw material preparation

SMC sheet: Select SMC sheet that meets the requirements of sanitary products. SMC sheet: must have waterproof, moisture-proof, corrosion resistance, high temperature resistance and other characteristics.

Other materials: such as sealant strips, hardware accessories (hinges, handles, etc.), drainage components, etc.

2. mold preparation

Mold design: Make molds according to the design drawings of the overall bathroom (including bath mold design: cylinder, sink, toilet, wall panel, ceiling, etc.) to ensure accurate size and reasonable structure.

Mold preheating: Heat the mold to a suitable temperature (usually mold preheating: 140℃-160 ℃) to ensure sufficient flow and solidification of the SMC material.

3. compression molding

Cutting SMC sheet: Cut SMC sheet according to mold size.

Charging: Place the cut SMC sheet into a preheated mold

Hot pressing: The SMC sheet is hot pressed in a mold at high temperature (140℃-160℃) and high pressure (10-20MPa), and the curing time is from a few minutes to ten minutes, depending on the thickness and size of the part.

4. cooling and demoulding

Cooling: The molded part is cooled in the mold to a suitable temperature (usually below 60°C).

Demoulding: Remove the molded bathroom parts from the mold.

5. post-processing

Trim: Remove excessive parts such as burrs and burrs.

Polishing: Polishing the surface of the part to ensure smoothness and level.

Drilling: Drilling holes are drilled into components for installation of fittings and pipes according to design requirements.

Surface treatment: Paint or other surface treatment to improve appearance quality and weather resistance.

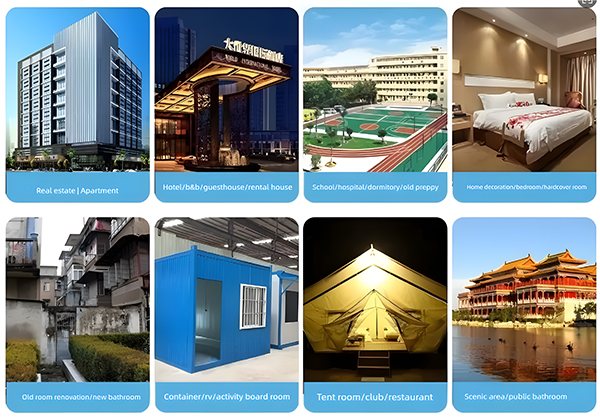

Product Application

Product parameters

Product details

1116 Product details

| Body | part name | specification model(mm) |

| SMC Molded Top Cover | 1100x1600White flat top | |

| SMC Molded Wall Panel | H=2200 Caesar beige/medium white | |

| SMC Molded Waterproof Chassis | 1100x1600brown squares | |

| PC door | 700x2000 vertical hinged door | |

| Floor drain for whole bathroom | Horizontal or straight | |

| Accessories | part name | specification model(mm) |

| face basin | SMC Molded P-Type Water Drop BasinL=1000 | |

| face basin bibcock | copper plating | |

| Basin water | flap type sewage | |

| cosmetic mirror | 500x700 mirror clip | |

| Square shelf | ABSwhite | |

| towel rack | L=400 ABS Base (white)+ stainless steel rod | |

| connected toilet | Ceramic top press type | |

| paper winder | ABSwhite | |

| shower | copper plating | |

| towel rack | L=400 ABS Base (white)+ stainless steel rod | |

| paper winder | ABSwhite | |

| bath curtain | L=1100bath cord | |

| Triangle shelf | ABSwhite | |

| LED downlight | fozhao4W-4000k | |

| ventilator | 210x210 Open-hole white (including exhaust hose) | |

| waterproof socket | Five-hole/with splash box |

ABOUT Runfa

Runfa Residential Technology (Changzhou) Co., Ltd. The company's registered capital is 62.88 million yuan and currently employs more than 300 people.

Runfa Residential Technology is mainly engaged in the research and development and production of SMC and BMC materials, and has gradually built an industrial chain with communications, power, overall sanitary ware, and environmental protection products as its main business goals. Its main products include:

1.Production of raw materials for SMC and BMC

2. Communication category: optical cable junction box, optical cable distribution box and sheet metal box

3. Power category: SMC materials such as TTU, FTU, and DTU and sheet metal boxes

4. Integral bathroom category: SMC molded top plate, wall plate and chassis, SMC mirror cabinet, SMC integrated basin

5. Environmentally friendly product categories: SMC waffle boards, etc.

6. Gas meter box: SMC molded gas meter box, stainless steel gas meter box

Runfa Residential Technology has strong production and processing capabilities. Currently, its main production and processing equipment includes 2 lines of SMC units, which can achieve an annual output of 30,000 tons, 30 hydraulic presses of various types, 11 injection molding machines, more than 10 sheet metal processing equipment such as digital punching, laser, and digital folding, and 4 pigtail production lines. The company has established a total of 7 workshops: SMC workshop, molding workshop, assembly workshop, painting workshop, sheet metal workshop, assembly workshop and injection molding workshop.

Runfa Residential Technology has a complete variety of box products and a large scale of SMC product production and processing in the communications industry and power grid industry. It has become one of the major suppliers in the national communications industry and power grid industry. The company adheres to the business philosophy of putting quality first and user satisfaction, and continuously improves the quality management system. It has passed ISO9001 quality management system certification