The color steel ceiling can adopt a lapped installation process (single-layer color steel plate) or a male and female splicing installation process (double-layer color steel plate), which has the advantages of fire prevention, environmental protection, and quick installation. The access port can be selected according to customer needs.

Key Features & Competitive Advantages

variously colored

green environmental protection

a-grade fireproof

size customization

Convenient maintenance

Product details

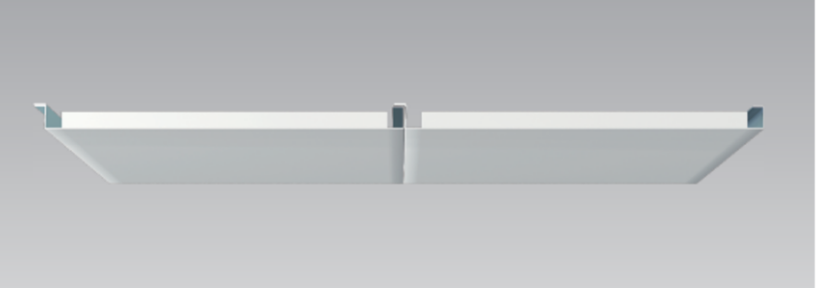

Single-layer ceiling assembly

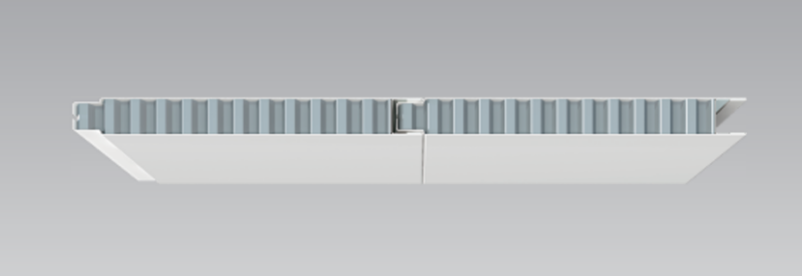

Composite ceiling assembly

| Feature | Single - layer Ceiling Parameters | Composite Ceiling Parameters |

| Plate Thickness | 0.5mm Film - covered Galvanized Steel Plate | 14mm |

| Inspection Opening | 450X450mm (Optional) | |

| Fire - Resistance Rating | Class A Fire - resistant Material | |

| Environment - friendly Material | Free of Formaldehyde, TVOC, Ammonia, Benzene and Other Harmful Indoor Gases | |

| Surface Material Type | White Surface, PVC Film | |

ABOUT Runfa

Runfa Residential Technology (Changzhou) Co., Ltd. The company's registered capital is 62.88 million yuan and currently employs more than 300 people.

Runfa Residential Technology is mainly engaged in the research and development and production of SMC and BMC materials, and has gradually built an industrial chain with communications, power, overall sanitary ware, and environmental protection products as its main business goals. Its main products include:

1.Production of raw materials for SMC and BMC

2. Communication category: optical cable junction box, optical cable distribution box and sheet metal box

3. Power category: SMC materials such as TTU, FTU, and DTU and sheet metal boxes

4. Integral bathroom category: SMC molded top plate, wall plate and chassis, SMC mirror cabinet, SMC integrated basin

5. Environmentally friendly product categories: SMC waffle boards, etc.

6. Gas meter box: SMC molded gas meter box, stainless steel gas meter box

Runfa Residential Technology has strong production and processing capabilities. Currently, its main production and processing equipment includes 2 lines of SMC units, which can achieve an annual output of 30,000 tons, 30 hydraulic presses of various types, 11 injection molding machines, more than 10 sheet metal processing equipment such as digital punching, laser, and digital folding, and 4 pigtail production lines. The company has established a total of 7 workshops: SMC workshop, molding workshop, assembly workshop, painting workshop, sheet metal workshop, assembly workshop and injection molding workshop.

Runfa Residential Technology has a complete variety of box products and a large scale of SMC product production and processing in the communications industry and power grid industry. It has become one of the major suppliers in the national communications industry and power grid industry. The company adheres to the business philosophy of putting quality first and user satisfaction, and continuously improves the quality management system. It has passed ISO9001 quality management system certification.