SMC Waffle Board are steel-concrete structures made with glass fiber reinforced plastic (epoxy glass fiber reinforced plastic) as templates. After pouring, the template is used as the bottom mold to meet the cleanliness requirements of general electronics factories. SMC waffle board is a structural material, but in order to improve certain properties, oriented SMC waffle boards can also be produced. Suitable for construction, transportation and packaging industries.

Characteristics of SMC Waffle Board

1. Using SMC waffle boards as templates can ensure accurate hole generation, high floor flatness and excellent flatness. The bottom edge and wall of the holes can be immediately used as decorative design layers.

2. It is produced and processed in a processing plant and can be installed immediately on the construction site. Easy to install, simple and practical to operate. Construction is faster and more reliable.

3. Choosing SMC waffle boards to replace the epoxy resin ceiling architectural coatings required in the purification workshop not only saves raw materials, but also saves the construction time of epoxy resin ceilings.

4. SMC waffle board solves the problems of large plate thickness, large dead weight of the bottom plate, and concentrated hole spacing.

5. The appearance and construction quality have been significantly improved. After the construction of the project, the roof was used as the base to eliminate common product quality problems such as cracking, peeling, and exposure of the roof of general concrete structures, saving costs. as well as the cost of maintenance and post-maintenance, and has an excellent appearance.

Product advantages

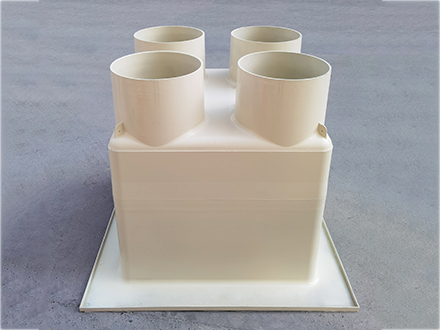

The four-direction facade is designed with a large arc shape, which greatly improves its pressure resistance and prevents product deformation during pouring.

There are multiple high-width reinforcing ribs from top to bottom on the 4-direction facade to improve the pressure resistance and fix them more firmly in the concrete.

Introduction to SMC Wafle Board Material and Fomming

1. Product requirements

Tensile strength: 50Mpa or more (according to ASTM D3039 test method)

Flexural strength: above 100Mpa (according to ASTM D790 test method)

Bending modulus: 8000Mpa or more (according to ASTM D790 test method)

Glass fiber content: 25%±5%(according to ASTM D2584 test method)

Flame retardant index: Comply with UL/HB (according to UL94 Burning Performance Test Method)

Oxygen index: ≥28 (according to GB/8624-1997 test method)

Acid and alkali resistance: According to GB3857 acid and alkali resistance test method, there is no change within 24 hours.

Analysis of VOC organic volatiles: according to GB18586-2001 (limit for hazardous substances in interior decoration and decoration materials)

2. Allowable error

long. Width: 1200mm, allowable tolerance +0-2mm

Pipe height: The nozzle plane of a 645-995mm straight pipe must be at right angles to the axis of the straight pipe, and the allowable tolerance is ± 1mm;

Pipe wall thickness: 4mm, allowable tolerance-0.5 mm, cylinder mouth end face local reinforcement>4mm

Aperture: Upper aperture 350-380mm, allowable tolerance is ±0.2% of design size

SMC formwork on-site construction steps

Test Report

| Test Results Page | ||||||

| / | Unit | Detection Reference | Technical Indicators (Provided by the Client) | detection result | determination | |

| Flexural Elastic Modulus | MPa | ASTM D790 - 2017 | ≥8000 | 8554.3 | meet | |

| Glass Fiber Content | % | ASTM D2584 - 2018 | 25±5 | 23.8 | meet | |

| Acid and Alkali Resistance | - | 10% Hydrochloric Acid for 24h | GB/T 3857 - 2017 | No visual change | There is no significant change in appearance color | meet |

| - | 10% Sodium Carbonate for 24h | No visual change | There is no significant change in appearance color | meet | ||

| Flammability Index(Horizontal Burning Rating) | Grade | UL 94 - 2023 | HB | HB | meet | |

|

Note: 1-The test results are only responsible for the customer's samples. We are not responsible for the true damage of the product and are not responsible for verifying the accuracy, appropriateness and integrity of the information provided by the customer; 2-The test results are only used for scientific research, teaching, internal quality control of the enterprise, enterprise product research and development, etc., and are not used as social justice figures. |

||||||

| Detailed Detection Data of Horizontal Burning | ||||||||||

| Unaged | After 70°C/168h Aging Test | |||||||||

| #1 | #2 | #3 | #4 | #5 | #1 | #2 | #3 | #4 | #5 | |

| Specimen Thickness (mm) | 5.14 | 5.12 | 5.22 | 4.99 | 5.15 | 5.19 | 4.98 | 4.95 | 4.93 | 5.06 |

| Whether Burns to 25mm Mark | No | No | No | No | No | No | No | No | No | No |

| Burning Rate (mm/min) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Whether Burns to 100mm Mark | No | No | No | No | No | No | No | No | No | No |

| Whether There are Dripping Flames or Drippings | No | No | No | No | No | No | No | No | No | No |

| Judgment (HB) | qualified | qualified | ||||||||

| Horizontal combustion test photos | ||||||||||

|

unaged |

Post 70℃/168h Aging Test |

|||||||||

Waffle board production and construction process